Sometimes supply a standard product that is close as possible to the customer needs it’s not enough, but it’s necessary to study some changes or additional components that can make it more suitable and efficient for its final use. In this way is designed and given to the client a unique, exclusive and PERSONALIZED product.

June 29 is the World Industrial Design Day, and in this occasion, we decided to talk about another type of custom design (we had already introduced the theme in the previous article “Personalization of the product”); this type is simpler, but also more requested: the drilling of the covers and accessories’ welding.

ARTEN gives the buyer the possibility to receive a product already complete, without necessarily having to modify it in autonomy.

We can make drillings on both manways and manholes; the client only needs to indicate the diameter of the hole inside the request and eventually its position… we’ll take care of the rest!

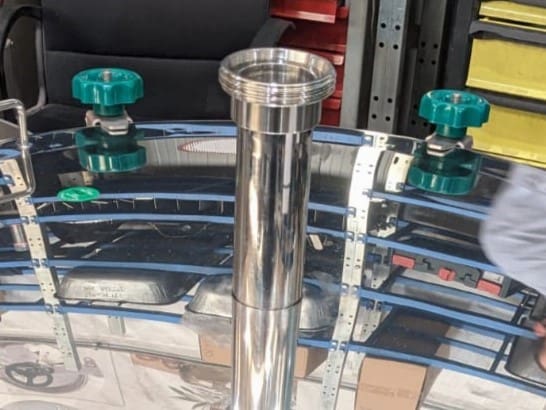

The drilling can be required without accessories or followed by the welding of one or more of them, such as valves, sight glasses or chimneys. In this case, knowing the diameter of the accessory is enough; the customer can find it by consulting the technical data sheets or our online catalogue.

For some clients we also studied the application of some parts which are not in the catalogue, like sleeves, flanges or additional hooks. Thanks to the collaboration of our technical department, a special drawing was prepared and then used as a guide by our production.

Sometimes, even just a small detail can make an article unique.

Here are some examples: